Which Adult Toy Material Truly Defines Your Brand's Success?

October 15, 2025 by

ellenyi@adultstoysgd.com

Product KnowledgeIs your brand struggling to navigate the complex world of adult toy materials? In a fiercely competitive market, a single wrong material choice doesn’t just impact user experience; it can directly erode your brand’s reputation, profitability, and long-term viability. The pressure to choose between cost-effectiveness and premium quality is immense. Opting for cheaper but riskier materials like PVC with phthalates might lead to product recalls, legal issues, and a catastrophic loss of customer trust. On the other hand, blindly investing in the most expensive materials like platinum silicone without a clear strategy can inflate your costs, pricing your products out of your target market. As a leading adult toy manufacturer, we know this dilemma intimately. This guide cuts through the noise, offering a strategic manufacturer’s perspective to help you make decisions that perfectly balance safety, performance, cost, and brand value.

The best material for your adult toy line is not a one-size-fits-all answer; it is a strategic decision dictated by your brand’s market position, target audience, budget, and long-term vision. For premium, luxury brands targeting discerning customers, platinum liquid silicone is unequivocally the gold standard due to its unparalleled body safety, durability, and luxurious feel. For mid-range brands aiming for a balance of quality and accessibility, high-grade, medical-safe silicone offers an excellent value proposition. For budget-conscious or entry-level product lines, materials like TPE and TPR can be viable, provided you partner with a reputable sex toy factory that guarantees quality control and phthalate-free composition. Ultimately, the "best" material is the one that aligns with your brand’s promise and is sourced from a trustworthy manufacturing partner.

But how do these material choices directly impact your OEM/ODM project’s timeline, customization options, and ultimate profitability? Let’s dive deeper.

People Also Ask (PAA) – A Manufacturer’s Insight

Here are the answers to the critical questions our B2B partners frequently ask:

➤ From a manufacturing standpoint, what’s the real cost difference between TPE and Silicone?

Silicone is generally 2-3 times more expensive per kilogram than TPE. However, the raw material cost is only part of the story. Silicone’s durability means lower mold degradation during high-volume production, reducing long-term costs. TPE’s faster injection molding cycle can slightly lower labor costs, but it requires more stringent quality control for porosity, potentially increasing inspection overhead.

➤ How does material choice affect possibilities for custom sex toy designs?

Material dramatically influences design freedom. Platinum liquid silicone excels in complex geometries, dual-density pours (a firm core with a soft exterior), and intricate surface textures. TPE is fantastic for ultra-soft, stretchy designs but is challenging for creating sharp, defined details. Glass and metal are rigid, limiting them to non-flexible forms, but they offer unique aesthetic possibilities through color and finishing that are impossible with elastomers.

➤ What is ‘platinum liquid silicone’ and is it worth the investment for a new brand?

Platinum liquid silicone is a premium-grade silicone cured using a platinum catalyst. This process results in a purer, more durable, and completely inert final product with no chemical byproducts, making it the safest option. For a new brand aiming for a high-end positioning, it’s a powerful statement of quality and safety that justifies a higher price point and builds immediate consumer trust.

➤ Are there reliable wholesale sex toys made in China that are body-safe?

Absolutely. The key is due diligence. Reputable manufacturers in China operate under strict international standards like ISO, CE, and RoHS. When sourcing, demand material safety data sheets (MSDS) and third-party lab test reports (e.g., for phthalates, heavy metals). A trustworthy adult toy manufacturer will be transparent and provide this documentation proactively.

➤ What quality certifications should I look for in an adult toy manufacturer?

Look for ISO 9001 (quality management systems), ISO 13485 (medical device quality management), CE marking (compliance with European standards), and RoHS (Restriction of Hazardous Substances). These certifications indicate a commitment to quality, safety, and consistent production processes, which is critical for OEM/ODM services.

➤ How does PVC vs. Glass impact shipping and logistics for wholesale orders?

This is a crucial business consideration. PVC is lightweight and durable, making it very cheap to ship in bulk. Glass, while robust, is heavy and requires significant protective packaging (padded boxes, inserts), which increases both the shipping weight and dimensional weight, driving up logistics costs for wholesale sex toys made in China.

➤ For OEM/ODM services, which material offers the fastest prototyping and production turnaround?

TPE/TPR generally offers the fastest turnaround. The materials are easier to work with, and their lower melting point allows for faster injection molding cycles. Silicone prototyping, especially for complex dual-density designs, requires more sophisticated tooling and longer curing times, extending the development phase.

Deep Dive into Material Analysis

Based on our industry expertise and extensive data from our production lines, here is a breakdown to guide your business decisions.

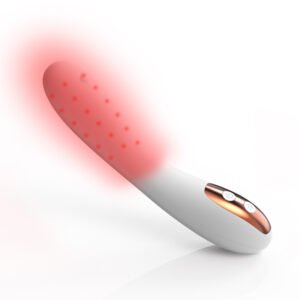

1. Silicone: The Industry Pillar 💎

- What it is: A highly versatile and body-safe polymer. It’s the go-to for vibrators, massagers, and premium dolls.

- Comfort: Its soft-but-firm texture feels incredibly skin-like. It warms to body temperature quickly, providing a natural and comfortable experience.

- Safety: Top-tier. Medical-grade and platinum liquid silicone are non-porous, hypoallergenic, and free from phthalates, latex, and BPA.

- Care & Storage: Effortless to clean with soap and water. Its non-porous nature prevents bacteria buildup. Crucially, store silicone toys separately from TPE/TPR toys, as direct contact will cause the TPE to break down and become sticky.

- Lifespan: With proper care, a high-quality silicone product can last for many years, offering excellent return on investment.

- Price: Moderately expensive. The price reflects its superior safety profile and longevity.

- Manufacturer’s Perspective / Business Insight:

- Production: Silicone molding is a precise science. Liquid silicone rubber (LSR) injection molding requires expensive, high-precision steel molds and machinery. However, it yields highly consistent results with minimal defects in mass production. According to our factory data, the defect rate for LSR molding is below 0.5%, compared to over 2% for some TPE products.

- Customization: Silicone offers fantastic custom possibilities. Hardness can be adjusted from ultra-soft (Shore 00-30) to quite firm (Shore A 40+). It’s the only material that allows for true dual-density casting, a key feature for premium realistic toys.

- Business Case: A brand investing in silicone is investing in its reputation. It signals a commitment to quality and safety that resonates with discerning consumers and justifies a premium price.

2. PVC: The Budget Contender 💰

- What it is: Polyvinyl chloride, a low-cost plastic often used for entry-level dildos.

- Comfort: Can range from rock-hard to jelly-like. It generally feels less natural than silicone and can have a distinct "plastic" smell.

- Safety: This is the major red flag. Traditional PVC contains phthalates to make it soft, which are known endocrine disruptors. While phthalate-free PVC exists, its porous structure remains a hygiene concern as it can harbor bacteria.

- Care & Storage: Requires meticulous cleaning. Never boil it. Its chemical instability means it can react with other toy materials.

- Lifespan: Poor. PVC degrades over 1-3 years, becoming brittle or sticky.

- Price: Very cheap, making it attractive for mass-market, low-price-point items.

- Manufacturer’s Perspective / Business Insight:

- Production: PVC is extremely cheap and easy to mass-produce via injection molding, leading to very low unit costs.

- Customization: Limited. While colors are possible, achieving sophisticated textures or multi-density effects is not feasible.

- Business Case: We advise extreme caution. While the low cost is tempting for wholesale orders, the associated health risks and poor durability can lead to brand damage. It is a material largely falling out of favor among responsible brands. If you must use it, demand rigorous third-party testing for phthalates.

3. TPE/TPR: The Soft Realist ☁️

- What it is: Thermoplastic Elastomer (TPE) or Thermoplastic Rubber (TPR). These are a class of copolymers that blend the properties of plastic and rubber. They are prized for their softness and are common in realistic masturbators and dolls.

- Comfort: Its primary selling point. TPE can be incredibly soft, fleshy, and stretchy, providing a hyper-realistic feel.

- Safety: A mixed bag. TPE is porous, requiring diligent cleaning to prevent bacterial growth. It’s generally phthalate-free, but always verify this with your sex toy factory. The material can feel slightly oily or sticky and often requires maintenance with cornstarch.

- Care & Storage: High maintenance. Must be cleaned thoroughly after each use and stored separately from all other materials, especially silicone.

- Lifespan: Shorter than silicone, typically 1-2 years, as its porous nature leads to faster degradation.

- Price: Significantly cheaper than silicone, offering a budget-friendly alternative for realistic-feel products.

- Manufacturer’s Perspective / Business Insight:

- Production: TPE manufacturing is fast and cost-effective. It has a lower melt temperature and faster cycle time than silicone. This makes it ideal for high-volume production of price-sensitive items.

- Customization: Excellent for softness and stretchiness. It’s the go-to material for products where a plush, yielding texture is paramount. However, color stability can be an issue, and it’s not suitable for integrated electronics like vibrators due to its lower heat resistance.

- Business Case: TPE is a strategic choice for specific product categories, particularly male masturbators and affordable dolls. For brands entering this segment, partnering with an experienced OEM/ODM provider is key to managing the material’s inherent porosity and ensuring a safe, consistent product.

4. Glass & 5. Metal: The Artisanal Luxuries ✨

- What they are: Borosilicate glass and medical-grade stainless steel are non-porous, rigid materials for premium massagers, plugs, and BDSM gear.

- Comfort: They offer a unique sensation—smooth, solid, and heavy. Their non-porous surface is exceptionally slick with lubricant. Their main advantage is temperature play (can be safely warmed or cooled).

- Safety: Flawless. Non-porous, hypoallergenic, and incredibly easy to sterilize (can be boiled or washed in a dishwasher). They are the epitome of hygienic.

- Care & Storage: Simple. Wash and store in a padded pouch to prevent scratches (metal) or chips (glass).

- Lifespan: Indefinite. These are "buy it for life" materials.

- Price: Moderate (glass) to expensive (metal).

- Manufacturer’s Perspective / Business Insight:

- Production: These materials are not molded but are shaped through lathing, grinding, and polishing (metal) or lampworking (glass). This is a more artisanal and labor-intensive process, leading to higher unit costs. They are not suitable for complex shapes achievable with molding.

- Customization: Customization is primarily in shape, size, and finish (e.g., polished vs. matte steel). Engraving or anodizing (for aluminum) offers branding opportunities.

- Business Case: Glass and metal products target a niche, high-end market that values aesthetics, hygiene, and durability over softness or flexibility. They serve as "halo products" that can elevate a brand’s entire portfolio. While not a volume driver, offering a curated selection can powerfully signal a brand’s commitment to luxury and quality.

In conclusion, selecting the right material is a cornerstone of your brand’s strategy, not just a technical detail. The ultimate decision rests on aligning material properties with your brand promise, and the most critical step is choosing an expert adult toy manufacturer who can guide you through these complexities and serve as a true partner in your success.

Latest Articles

February 18, 2026

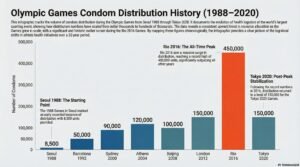

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is