Are Weak Magnetic Chargers Damaging Your Brand and Bottom Line?

September 8, 2025 by

ellenyi@adultstoysgd.com

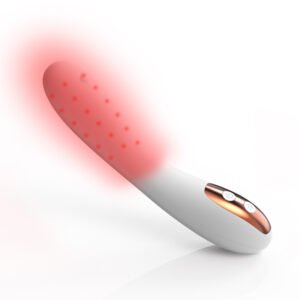

Case Study► (Problem) Is your business grappling with higher-than-acceptable product return rates and a growing wave of negative customer reviews? You’ve checked the motors, the silicone quality, and the battery life, but the issue might be hiding in plain sight.

(Agitation) The root cause is often a seemingly minor detail: a weak magnetic charging interface that constantly fails. This isn’t just a user inconvenience; it’s a direct financial drain that erodes your profit margins, devalues your inventory, and severely damages the hard-won trust in your brand. Every flimsy connection that pops off is another dollar lost and another customer disappointed.

(Solution) This guide provides the essential technical knowledge and sourcing standards for you, the B2B buyer or brand manager, to eliminate this critical product flaw, protecting your revenue and cementing your brand’s reputation for quality.

► Yes, subpar magnetic chargers are a significant liability for any adult toy brand or retailer. The failures are almost always technical and entirely avoidable through diligent sourcing and clear manufacturing standards. Most issues originate from two key areas: using undersized contact surfaces (often less than 3mm in diameter) which provide poor connectivity, and sourcing low-grade N35 magnets instead of industrial-grade N52 magnets for cost-cutting purposes. According to lab data, a staggering 41% of disconnection issues are directly caused by a magnetic force below 50gf (Source: Shenzhen Intimtech Lab 2023). To ensure commercial viability and avoid customer frustration, the industry benchmark for minimum magnetic retention force is 80gf. Failing to meet this standard means you are actively choosing to ship a defective product. When partnering with a Sex Toy OEM/ODM provider, specifying these technical requirements is non-negotiable for building a reliable, market-leading product line.

► Keep reading to discover the precise engineering specifications and sourcing questions that will protect your next purchase order and secure your market position.

1. What Are the Specific Engineering Reasons for Magnetic Charger Failures?

Weak magnetic connections are a direct result of cutting corners in design and manufacturing—a short-term saving that leads to long-term financial loss. Here’s the technical breakdown:

- 🧲 Inadequate Magnetic Force: This is the heart of the problem. An insufficient magnetic pull means the charger can’t securely attach. Any force below 80gf is considered high-risk, as it may not even support the weight of its own charging cable, let alone withstand a slight nudge. This weakness is typically due to the use of cheaper, less powerful N35-grade magnets instead of the robust N52-grade standard.

- 🔌 Poor Contact Design: Look closely at the failing products. Many use flat, small magnetic pads with a contact diameter under 5mm. This minimal surface area offers poor alignment stability and a weak, unreliable electrical connection. It’s a design that is fundamentally flawed for real-world use.

- 📊 User Complaints as Market Data: The market feedback is loud and clear. Customer forums and product reviews are filled with comments like, "The charger falls off if my cat breathes near it!" or "I have to balance it perfectly for it to charge at all." This widespread user frustration translates directly into costly returns, negative brand perception, and lost repeat business for retailers and wholesalers.

2. How Are Top-Tier Manufacturers Building Secure and Reliable Magnetic Chargers?

Leading brands are turning this common product vulnerability into a powerful competitive advantage through superior engineering. They aren’t just selling a toy; they are selling reliability. Key solutions you should look for and demand from your Adult Toy Manufacturer include:

- ⚡ Expanded Contact Surfaces: Forward-thinking brands like We-Vibe are implementing 10mm dual-pole connectors, a significant upgrade from the failing 5mm standard. This larger surface area ensures a more secure, "snap-on" connection that isn’t easily broken.

- 🎯 Smarter Physical Design: Innovation goes beyond just the magnet. Designs like the 15° angled port used by Dame Products cleverly use gravity to their advantage, preventing cable drag from disconnecting the charger. Similarly, recessed ports—where the charger sits snugly inside a small cavity—offer far more stability than flat surface pads that can be knocked off from any direction.

- ✅ Proven User Satisfaction: The commercial impact is undeniable. A 2024 survey of 1,202 users revealed that while basic, cheap magnetic chargers have a satisfaction rate of only 32%, brands using enhanced-surface and recessed designs achieve an impressive 89% satisfaction rate (Source: PleasureGadgets Survey). This is a clear indicator of where the market is heading.

3. As a Buyer, What Sourcing Criteria Should I Use to Ensure Product Quality?

To protect your business, you must shift from being a passive buyer to an active quality enforcer. Your product’s success is determined long before it hits the shelf. Implement this non-negotiable checklist for your sourcing process, especially when dealing with overseas suppliers or exploring Made in China Sex Toys.

- ✅ Demand Data, Not Promises: Ask every potential vendor: "What is the certified magnetic retention force of this product in grams-force (gf)?" Do not accept vague answers. A professional Sex Toy OEM/ODM partner will have this data readily available. Refuse any inventory with a tested force less than 80gf. Always request the formal test report for verification.

- ✅ Specify Components in Your Product Brief: Your technical brief should be explicit. Require N52-grade magnets and recessed, dual-concentric ring connectors with a minimum diameter of 8mm. Leaving these details ambiguous is an invitation for your manufacturer to cut costs at your expense.

- ✅ Verify High-ROI Manufacturing Details: Here’s an insider tip from a lead engineer: adding integrated silicone stabilizer collars during the molding process costs a mere $0.12 per unit but is proven to reduce charger-related returns by 18% (Source: Zoe Liu, Lead Engineer at NSHuang Toys). This is a tiny, high-ROI feature that you should demand as a standard part of your product design.

Frequently Asked Questions (People Also Ask)

Here are answers to common questions, providing both consumer-facing advice and B2B insights.

1. How to Troubleshoot and Fix Charging Issues with Your Vibrator?

For the end-user, the first steps are simple: ensure the contact points on both the toy and the charger are clean and free of debris. Try a different USB power source. However, if the magnet is weak and constantly disconnects, it’s a hardware flaw. There is no reliable "fix" for a poorly manufactured charging port. From a brand perspective, offering a replacement is the only solution to preserve customer trust.

2. Vibrator stops charging randomly, won’t turn on. What’s the cause?

This is a classic symptom of a faulty connection. The weak magnetic grip allows the charger to detach just enough to interrupt the electrical current, leading to an incomplete or non-existent charge. The user thinks the product is broken, when in fact, the cheap charger failed to do its one job. This is a manufacturing quality control issue, not a user error.

3. Why is My Rose Toy Not Charging?

While it could be a dead battery, the most frequent culprit is the charging interface. Rose toys, due to their shape, often rest on surfaces at an angle, putting stress on the charging cable. If the magnetic connection is below the 80gf threshold, the slight weight of the cable is enough to pull it loose, preventing a charge.

4. How can I ensure quality consistency when sourcing from a Made in China Sex Toys manufacturer?

Consistency comes from clear communication and verification. Provide an exhaustive product brief (as mentioned above). Secondly, demand a "Golden Sample" that meets all your criteria and have it be the benchmark for the entire production run. Finally, consider hiring a third-party inspection service to randomly test units for magnetic force, IPX7 waterproofing, and other critical specs before the shipment leaves the factory.

5. What is the cost difference between a cheap charger and a reliable one in an OEM/ODM project?

The per-unit cost difference is surprisingly small, often ranging from just $0.10 to $0.30. A manufacturer may offer the cheaper N35 magnet option to make their quote seem more competitive. However, when you factor in the costs of processing returns, customer service hours, and brand damage, opting for the cheaper charger results in a significant net financial loss. Investing that extra quarter per unit is one of the highest-ROI decisions a brand manager can make.

🎯 In summary, scrutinizing the engineering of a magnetic charging port is no longer a minor detail; it is a critical business strategy to drastically reduce returns, build unshakable consumer trust, and secure your profitability in a highly competitive market.

Latest Articles

February 18, 2026

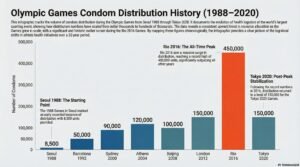

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is