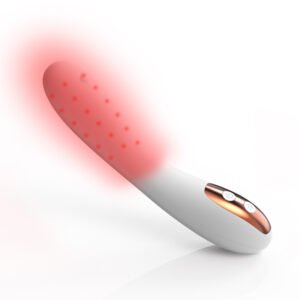

Can Your Custom Medical Grade Liquid Silicone Vibrator Manufacturer Deliver a Miracle in Just 35 Days?

December 25, 2025 by

ellenyi@adultstoysgd.com

Case StudyIs your supply chain giving you anxiety rather than confidence?

Picture this: You have a brilliant idea for a new couple intimate healthy device. You have investors waiting, a marketing plan ready, and a launch date set. But then, your supplier goes silent. The samples arrive late, and worse—they are defective. The mold is off-center, the material tears, and your emails go unanswered. The fear of missing your market window is real, and it disrupts your sleep. This is the nightmare many Brand Buyers face when sourcing overseas. But it doesn’t have to be this way. Imagine a partner who cleans molds at 3 AM alongside you just to ensure you catch your flight with a perfect product. We did exactly this for the Dr. Gallini Clinic project, turning a crisis into a triumph in just 35 days.

What defines a reliable medical-grade silicone toy manufacturer?

A top-tier custom Medical Grade Liquid Silicone Vibrator manufacturer does more than just process rubber; they offer comprehensive crisis management and rapid engineering solutions. Key indicators of reliability include the ability to execute cross-functional problem solving (design, mold, and material teams), strict adherence to ISO 10993 biocompatibility standards for couple wellness products, and a proven track record of delivering complex OEM/ODM projects using precise silicone pouring techniques under tight deadlines without compromising physical properties.

Keep reading to discover how we battled against the clock, solved critical engineering failures, and helped a client launch a market-disrupting product when everyone else said it was impossible.

People Also Ask: 7 Critical Questions B2B Buyers Ask About Silicone Manufacturing

Here are the honest answers you won’t always get from a typical factory:

- Q: How do you prevent “eccentricity” (off-center defects) in full-silicone vibrators?

A: We use a precise internal “positioning rod” structure to anchor the mold core, ensuring the liquid silicone fills evenly around the hardware without shifting during the pouring process. - Q: What is the difference between standard silicone and Medical Grade Liquid Silicone (LSR)?

A: LSR is platinum-cured, offers superior purity, withstands higher temperatures, and meets biocompatibility standards (like USP Class VI) required for adult healthy wellness accessories. - Q: Can you handle urgent mold modifications during the trial phase?

A: Yes. We deploy emergency teams (mold engineers, designers, and production heads) to work 24/7 shifts, modifying tooling overnight to meet flight deadlines. - Q: What happens if the silicone hardness (Shore A) feels wrong on the first sample?

A: We stock various raw material grades. If a sample feels too stiff, we can switch liquid raw materials immediately during the trial run to achieve the perfect “skin-like” feel. - Q: Do you offer OEM/ODM services for complex medical-grade designs?

A: Absolutely. We specialize in turning conceptual sketches into manufacturable 3D designs, managing everything from PCB integration to final silicone overmolding. - Q: How do you ensure intellectual property protection for my unique design?

A: We sign strict NDAs and ensure that your molds are stored securely, accessible only to authorized personnel involved in your couple wellness product production. - Q: Why is “Flash” or “Tearing” common in new molds, and how do you fix it?

A: It often stems from uneven parting lines or demolding issues. We fix this by optimizing the mold structure and refining the release process, sometimes manually assisting until the tool is perfect.

The 35-Day Challenge: A Story of True Grit and Engineering

Let me take you back to a chilly November. This isn’t just a story about manufacturing; it’s a story about human connection and the relentless pursuit of perfection.

On November 4th, we shook hands with a prestigious client regarding the Dr. Gallini Clinic project. Their request was specific: a high-end, medical-grade liquid silicone wearable vibrator designed to enhance couple intimacy. The timeline? Brutal. The client needed to fly back with a “Golden Sample”—a flawless, production-ready unit—by December 20th. We had exactly 35 days to go from a handshake to a finished product.

🚀 The First Obstacle: The Failure

Speed often reveals weaknesses. During our first trial run (T1), disaster struck. The mold factory, due to a communication gap, missed a critical design element: the positioning rod.

Here is exactly what went wrong: Because there was no center positioning rod to secure the internal structure, the mold core shifted during the silicone pouring process. This resulted in severely uneven wall thickness—one side was too thick, and the other was critically thin. Consequently, when pulling out the mold core, the thin side would simply snap and tear. It was a mess.

Many suppliers would have blamed the mold maker and waited weeks for a fix. We didn’t have weeks. We didn’t even have days.

💡 The Strategy: The War Room

We immediately formed a crisis discussion group. I pulled everyone into one room: the mold engineers, the industrial designers, the structural engineers, the silicone raw material suppliers, and the production boss.

We realized that for a large, solid liquid silicone product, we needed a viable positioning rod to effectively fix the center point. We redesigned the internal structure on the spot to ensure the core remained perfectly centered during the pouring phase, allowing for safe core extraction later.

The Final Countdown: Sleepless in the Factory

The second trial (T2) was scheduled right before the deadline. The client’s flight was at 7:00 PM on December 20th. This was our “do or die” moment.

From December 17th to 19th, our mold factory partners pulled an all-nighter, every single night, working until 3 AM and restarting at sunrise. They finished the modified mold on the afternoon of the 19th.

I moved into the factory with the client. We set up a temporary station right next to the pouring machines.

Then, another problem hit. ⚠️

We were testing two different silicone hardness levels to find the perfect texture for a couple intimate healthy device. The material wasn’t behaving clearly.

I didn’t call a cleaner. I rolled up my sleeves, grabbed the tools, and started cleaning the mold myself. I wanted to make sure every speck of dust was gone. On the night of the 19th, as we ran the machine, we realized the silicone grade was too sticky. I made the call: “Change the material. Now.”

We switched the raw material barrels at midnight. The mold technician, the raw material engineer, the factory boss, and I—we all stood there, eyes red from lack of sleep, watching the machine cycle.

At 4:00 AM, the perfect sample cured. It was centered. Using the new positioning rod, the core pulled out smoothly without tearing. It was flawless.

We battled until the final second. When the client boarded that plane on the 20th, they didn’t just carry a product; they carried the result of a team that refused to give up. They were moved not just by the quality, but by our sincerity.

Why the Market Demands “Medical Grade” Excellence (And Why You Should Too)

This story isn’t just about hard work; it reflects a massive shift in the global market.

According to 2024 industry data, the global adult toy market is valued at over $36 billion, growing at a CAGR of 8-9%. But the real money isn’t in cheap, novelty items anymore. The data shows a massive pivot towards “Wellness” and “Health.”

Consumers are smarter. They read labels. They demand:

- Biocompatibility: Products that are safe for internal use (ISO 10993 compliant).

- Longevity: Silicone that doesn’t degrade or get sticky over time.

- Experience: A “skin-like” touch that only high-quality LSR can provide.

As a B2B buyer, sourcing cheap PVC or low-grade TPR is now a liability. Your customers are looking for medical-grade liquid silicone.

However, working with LSR is technically difficult. It requires exact molds and precise process control. If your made in China partner doesn’t understand the nuance of “pouring liquid silicone” or how to stabilize a mold core, you will face delays.

Our Advantage:

We don’t just sell products; we sell the certainty that your complex design will be manufactured correctly. We understand that a couple wellness product must be perfect because it touches the most intimate parts of a human life. We treat your timeline as our own.

Conclusion

Creating a new product is never easy, but with the right reliable partner, it is always possible. Whether it involves re-engineering a mold overnight or scrubbing a machine at dawn, we do whatever it takes to put the perfect sample in your hands.

Are you ready to work with a supplier who cares as much about your product as you do? Contact us today, and let’s build your next bestseller.

Latest Articles

February 18, 2026

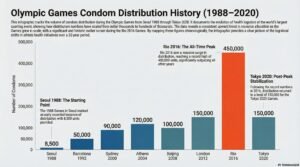

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is