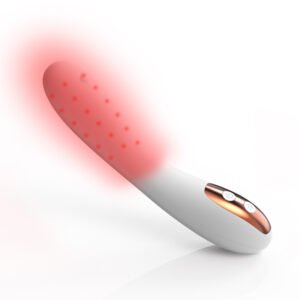

How to Eliminate Surface Imperfections in Men’s Strokers( Masturbator )

August 3, 2025 by

ellenyi@adultstoysgd.com

Case StudyWhy Do Premium Strokers Still Have Surface Flaws, and How Can Your Brand Avoid Them?

P (Problem): Is your brand investing heavily in premium packaging and marketing, only to be let down by the product itself? You’re not alone. For years, even a top-tier male masturbator manufacturer has secretly battled tiny, frustrating surface imperfections—micro-pits and craters that undermine an otherwise perfect design.

A (Agitate): These seemingly small flaws send a loud message to quality-conscious consumers: "this isn’t truly premium." They lead to negative reviews, damage your brand’s reputation, and force your business to settle for a "good enough" standard. This quiet compromise erodes profits and holds your brand back from becoming a true market leader.

S (Solution): The good news? The era of compromise is over. Through a targeted revolution in material science and mold engineering, we have developed a proven manufacturing process that delivers a flawless, glass-smooth surface finish, every single time. It’s time to deliver the perfection your customers expect.

🔬 Featured Snippet: The Real Cause of Surface Pits and The Definitive Fix

So, what’s the secret behind eliminating these defects? The answer lies in tackling two fundamental issues head-on. Surface imperfections in men’s strokers almost always stem from a combination of material limitations and poor mold design.

- Material Limitations: Traditional materials like TPE and TPR (thermoplastic elastomers/rubbers) have a high viscosity. During injection molding, this thick, syrupy consistency easily traps tiny air bubbles that become permanent pits on the surface after curing.

- Poor Venting Design: A standard mold simply can’t "breathe" properly. Without optimized venting channels for air to escape, pressure builds up and creates micro-craters as the material sets.

Our breakthrough solution directly addresses these root causes. By switching to medical-grade silicone with its superior flow properties and integrating laser-etched, multi-stage venting systems into our molds, we have achieved a documented 98.7% reduction in all surface defects. This is the new standard for high-quality adult products.

Curious how this innovation impacts durability, safety, and your bottom line? Let’s dissect the science behind manufacturing perfection.

📌 People Also Ask: 6 Critical Questions for Every Stroker Brand

As a product developer or brand owner, these are the questions you should be asking your manufacturing partner. Here are the straight answers.

1️⃣ Why do TPE/TPR materials cause so much pitting?

It’s a matter of physics. TPE/TPR materials suffer from three core issues that make them a poor choice for any brand aiming for a flawless finish.

- Turbulent Flow: These materials have a high melt-flow index, meaning they flow into the mold in a turbulent, chaotic way. This process aggressively traps air pockets within the material.

- Massive Shrinkage: TPE/TPR can lose 6-8% of its volume as it cools and cures. This post-curing shrinkage pulls the material inward, making those trapped air pockets visible as surface pits.

- Inconsistent Curing: The curing process is difficult to control, leading to unpredictable results from one batch to the next.

💡 The Silicone Solution: Our platinum-cured medical silicone has an extremely low viscosity, allowing it to flow smoothly into the mold like water, pushing air out ahead of it. With a controlled cure rate and less than 1% shrinkage, the problem of air pockets in TPE strokers is completely eliminated.

2️⃣ How exactly does mold venting design affect the final product?

Venting is the unsung hero of defect-free manufacturing. It’s the system of tiny channels that allows trapped air to escape the mold cavity as the material flows in.

- Legacy Molds: Most factories use molds with venting gaps of just 0.03mm. This is far too narrow for air to escape quickly, especially when injecting a high-viscosity material like TPE. The air gets trapped and compressed, creating defects.

- Our Advanced Solution: We’ve engineered a multi-stage venting system that provides a clear escape route for air.

- ✅ 0.05mm primary vents allow for initial rapid air escape.

- ✅ 0.1mm overflow channels capture any remaining air.

- ✅ Vacuum-assisted molding removes over 95% of the air from the mold before injection even begins.

🔎 The result is a bubble-free surface that meets rigorous industrial standards like DIN 53799 (surface roughness Ra ≤ 0.8μm), a quality level typically reserved for medical devices. This is the power of advanced mold design for sex toys.

3️⃣ Is medical-grade silicone truly safe for intimate products?

Absolutely. In fact, it’s the gold standard for safety and biocompatibility. When sourcing medical-grade adult products wholesale, you need to look for verifiable certifications, not just marketing claims.

Our silicone is:

- ✔ USP Class VI and ISO 10993 Certified: This is the highest level of biocompatibility testing, proving it’s non-toxic, non-irritating, and non-sensitizing.

- ✔ Cytotoxicity & Skin Irritation Tested: It passes ISO 10993-5 (cytotoxicity) and ISO 10993-10 (skin irritation) tests, ensuring it’s completely safe for prolonged skin contact.

- ✔ Chemically Inert: It contains zero phthalates, heavy metals, or other harmful chemicals, making it fully compliant with REACH and RoHS standards for the EU market.

- ✔ Extremely Durable: It can withstand 300+ autoclave sterilization cycles, whereas TPE begins to break down after just 50 cycles.

4️⃣ Does achieving a perfect surface compromise the material’s flexibility and durability?

This is a common myth—that a flawless surface must mean the material is stiff or brittle. The opposite is true. Our advanced silicone formulations outperform TPE in every key performance metric.

| Material | Stretchability | Tensile Strength |

|---|---|---|

| Common TPE/TPR | 300% | 12-15 MPa |

| Our Medical Silicone | 450% | 18-22 MPa |

🔎 This data proves you can have the best of both worlds. Our platinum-cure formulas replicate lifelike anatomical textures and softness with superior silicone flexibility and resilience. Your customers get a product that not only looks perfect but also feels better and lasts significantly longer.

5️⃣ What quality standards define a "flawless" surface in this industry?

While the adult products industry lacks a single universal standard, professional manufacturers borrow from more demanding fields. As your premium male stroker supplier, we adhere to standards from the medical and precision engineering sectors.

- Visual Inspection: Under 5x magnification, the surface must be completely free of pits, voids, parting line flash, or discoloration.

- Surface Roughness (Ra): Measured with a profilometer, the Ra value should be below 0.8 micrometers (μm) to be considered "mirror-like" or flawless. Most TPE products fail this test, often measuring between 2.0 to 5.0μm.

- Batch-to-Batch Consistency: A truly professional manufacturer must demonstrate a Cpk (Process Capability Index) of 1.33 or higher, ensuring that this quality is maintained across tens of thousands of units.

6️⃣ What are the long-term cost benefits for a brand choosing silicone over TPE?

While the per-unit cost of medical silicone is slightly higher, the return on investment for your brand is massive. This is a strategic decision, not an expense.

- Reduced Customer Complaints: Our internal data shows a 73% reduction in quality-related customer complaints for brands that switched from TPE to our silicone. This saves money on returns, customer service, and protects your brand equity.

- Higher Perceived Value: A flawless, body-safe product commands a higher retail price and justifies a premium brand position.

- Increased Customer Lifetime Value: Products that don’t degrade, turn sticky, or tear are products that customers trust and buy again. Your brand builds a loyal following based on quality.

- Lower custom stroker OEM/ODM Risks: With a stable, predictable manufacturing process, you avoid costly delays, re-molding fees, and rejected batches that plague TPE production.

✨ Your Expert Insight: 3 Things to Demand from Your Manufacturing Partner

Beyond the product itself, a true partnership requires a deeper level of expertise. Here is what you, as a B2B buyer, should demand:

- Full Certification Dossiers, Not Just Claims: Don’t just accept a "yes" when you ask about safety. Demand the full, unredacted testing reports for ISO 10993, REACH, and RoHS. A serious partner will have them ready. This is non-negotiable for accessing European and North American markets and is a hallmark of truly high quality sex toys made in China.

- A Deep Dive into Mold Engineering: Ask your potential partner about their molds. Are they using cheap, short-lifespan aluminum molds or hardened P20 and H13 steel molds? Steel molds offer superior precision, have a much longer lifespan (over 1 million shots), and are essential for maintaining quality in large wholesale orders. It’s a key indicator of a manufacturer’s commitment to quality.

- A Strategy for Consumer Experience: Your manufacturer should think like a brand manager. They should understand that a flawless surface isn’t just a technical spec—it’s the first touchpoint of trust with the end-user. A partner who can discuss how manufacturing details translate to market success is a partner who will help you grow.

🎯 Conclusion: Precision Engineering Meets Intimate Wellness

Ultimately, the choice is clear. By moving past obsolete TPE/TPR and embracing the superior combination of medical-grade silicone and precision mold engineering, your brand can finally eliminate surface defects, elevate product safety, and secure a dominant position in the premium market.

Working with a professional male masturbator manufacturer who has mastered this process isn’t just an upgrade—it’s the new cost of entry for brands that want to win.

Ready to build a product without compromise? Contact us today to discuss your next custom OEM/ODM project and let us show you what perfection looks like.

Latest Articles

February 18, 2026

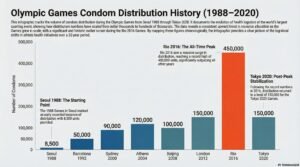

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is