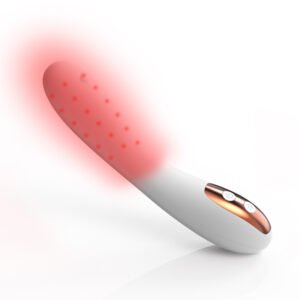

How to Make a Silicone Dildo: A Step-by-Step Guide

June 30, 2025 by

ellenyi@adultstoysgd.com

Product KnowledgeHow a Top Silicone Dildo Manufacturer Crafts Your Products: A Step-by-Step Guide

Are you curious about how those incredibly realistic dildos and other high-quality adult toys are actually manufactured? Whether you are a brand procurement specialist, a wholesaler sourcing new inventory, or a platform retailer ensuring product quality, understanding the production process is vital. It’s the key to guaranteeing you source safe, durable, and market-ready products. From the initial design concept to the final quality inspection, every single step is critical to delivering body-safe pleasure products that meet and exceed international standards.

🔍 What Is the Complete Process of Manufacturing a Silicone Dildo?

This intricate manufacturing journey can be broken down into several core stages. The process meticulously involves:

✔ Designing & Prototyping

✔ Precision Mold Creation

✔ Medical-Grade Silicone Mixing

✔ Pouring & Curing

✔ Finishing & Quality Control

For more advanced products like suction cup dildos, strap-on dildos, or a modern dildo vibrator, additional components such as stable bases, powerful motors, or complex mechanisms are seamlessly integrated. Below, we break down each stage in detail, helping you evaluate suppliers and ensure absolute product excellence for your brand.

Ready to learn what goes into crafting premium silicone dildos that customers love? Let’s dive in!

🎨 1. Design and Sculpting: Crafting the Perfect Shape

The foundation of any great realistic dildo or innovative fantasy design begins right here. This is the stage where ideas become tangible.

- ✏️ Sketching & 3D Modeling: Professional designers create detailed 2D sketches or sophisticated 3D digital models. The focus is always on ergonomics, aesthetics, and user experience. This is especially crucial when developing a completely custom silicone dildo.

- 🖌️ Sculpting: From the digital model, artists use professional-grade clay or wax to hand-sculpt a master prototype. This allows them to create incredibly lifelike textures, veins, and innovative shapes that digital models alone cannot capture.

🌟 Why It Matters: A well-designed and beautifully sculpted prototype ensures market appeal and perfect functionality. Whether it’s for a standalone product or a complex strap-on, this initial stage dictates the final product’s success.

🔧 2. Mold Creation: Precision for Scalable Production

The mold is the heart of mass production. It must be perfect to capture every single vein, curve, or the unique base of a suction cup dildo with flawless accuracy.

- ⚙️ Material: High-grade, durable silicone or precision-milled aluminum molds are used. Aluminum molds are more expensive but offer unparalleled durability and precision for very large production runs, a hallmark of experienced OEM/ODM adult toys manufacturers.

- 🔄 Process: The sculpted prototype is suspended inside a mold box. Liquid silicone rubber is then carefully poured over it, capturing every minute detail. After curing, this forms a negative impression of the prototype—the production mold.

💡 Pro Tip: For suction cup dildos, the mold design is engineered to include the flared base shape, ensuring a strong and reliable suction cup is formed in one piece with the dildo.

🧪 3. Silicone Preparation: Safety and Quality First

The choice of material is non-negotiable for any reputable brand. Only medical-grade platinum-cured silicone is used. This material is non-toxic, hypoallergenic, and fully compliant with demanding international standards like FDA and CE.

- ⚗️ Mixing: The silicone base and the platinum catalyst are blended in precise ratios to ensure a perfect cure and final product feel. This is done in a controlled, clean environment.

- 🎨 Additives: High-quality, skin-safe pigments are added to achieve specific colors, like realistic flesh tones or vibrant fantasy shades. Softeners can also be blended in to create dual-density products (firmer inside, softer outside).

⚠️ Key Point: Unscrupulous manufacturers may use cheap silicones with fillers like oil or powder to cut costs. Always verify material certifications from your supplier! The best partners, often found among top-tier producers of sex toy made in China, will eagerly provide this documentation.

🔥 4. Pouring and Curing: Ensuring Structure and Durability

This is where the liquid silicone takes its final, solid form. Precision is key to avoiding defects.

- 🌀 Pouring: The mixed silicone is poured slowly and steadily into the mold. This is often done in a vacuum chamber to remove any trapped air bubbles. Air bubbles can create weak spots or ruin the aesthetic, and are especially problematic for a dildo vibrator as they can create internal voids around the motor.

- ⏳ Curing: The filled molds are then left to cure. This can happen at room temperature over 24 hours or be accelerated in an industrial oven, which reduces the time to 4–6 hours while ensuring a complete and even cure.

🔌 For Vibrating/Thrusting Dildos: For vibrating or thrusting models, the waterproof motor compartment or the core thrusting dildo mechanism is carefully inserted into the mold before the silicone is fully poured and cured, encasing it seamlessly.

✂️ 5. Demolding and Finishing: The Final Polish

Once cured, the dildo is carefully removed from its mold. It’s not quite finished yet; the final touches are what create a premium feel.

- 🔪 Seam Removal: A thin line of excess material (a "seam") is left where the mold parts meet. Skilled workers meticulously trim this away by hand, then polish the surface to ensure it is perfectly smooth and seamless.

- ✅ Quality Checks: Every single realistic dildo is inspected for any defects, such as air bubbles, imperfections, or color inconsistencies. Special attention is paid to suction cup dildos to check base adhesion and strap-on dildos for O-ring compatibility. A trusted dildo vibrator supplier will have a multi-point inspection process.

⚡ 6. Assembly (For Specialized Electronic Products)

For advanced toys, this is the final technical step.

- 📳 Vibrating Dildos: The waterproof motors are embedded, batteries (if applicable) are installed, and any control buttons or charging ports are sealed to ensure they are fully waterproof.

- 🔄 Thrusting Dildos: The internal thrusting mechanisms are installed and tested for speed, function, and noise levels to ensure they provide a smooth and powerful user experience.

🧼 7. Sterilization and Packaging

The final step before the product is ready to ship to you.

- 🚿 Cleaning: Products are washed in an antimicrobial solution and thoroughly dried in a clean-room environment to ensure they are completely sterile.

- 📦 Packaging: Products are placed into their retail-ready boxes along with user manuals and charging cables. All packaging includes necessary compliance labels (like ROHS, CE, and REACH).

💰 For Wholesalers: Reputable manufacturers can offer efficient bulk packaging options to help reduce shipping costs and streamline your inventory process.

🤝 Why Partner with a Professional Silicone Dildo Manufacturer?

Working with a professional isn’t just a choice; it’s a strategic business decision.

- ✔ Consistency: High-quality molds and standardized processes allow for the scalable production of thousands of identical, perfect realistic dildos, suction cup dildos, and more.

- ✔ Safety & Compliance: A professional silicone dildo manufacturer uses only certified medical-grade silicone, which protects end-users and shields your business from legal risks and recalls.

- ✔ Customization Expertise: They have the engineering and design teams to help you adapt existing designs or create entirely new products for niche markets, from strap-on dildos to complex electronic toys.

🔚 Final Thoughts

Understanding this meticulous process—from sculpting lifelike textures for realistic dildos to integrating sophisticated vibrating or thrusting features—empowers wholesalers and retailers. It gives you the knowledge to source superior, compliant, and highly desirable products, ensuring your brand is known for quality and safety.

Latest Articles

February 18, 2026

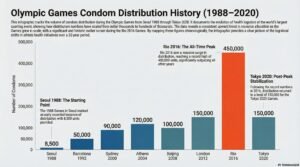

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is