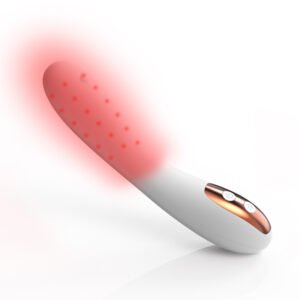

What Should Brands Know About Silicone Material and Structural Design When Customizing Sex Toys?

July 7, 2025 by

ellenyi@adultstoysgd.com

Product KnowledgeWhat Do Brands Really Need to Know Before Partnering with a Sex Toy Manufacturer?

P: So, you have a brilliant idea for a customized sex toy. You can picture the design, the branding, and the ecstatic customer reviews. But then you hit a wall: the complex world of silicone materials, Shore hardness, and structural engineering. You’re trying to communicate your vision to a potential sex toy supplier, but the technical jargon feels like a foreign language, and you’re terrified of making a multi-thousand-dollar mistake.

A: This uncertainty is where amazing concepts die. Brands without deep manufacturing knowledge often end up with products that are uncomfortable, unsafe, or simply impossible to produce at scale. They face budget overruns from incompatible materials, production delays that miss crucial market windows, and the ultimate nightmare: a warehouse full of products that fail to sell, tarnishing the dream of launching their own brand sex toy.

S: But it doesn’t have to be this way. Imagine having a direct line to over seven years of industry expertise, demystifying the entire process. This guide is your playbook. We will break down the critical alignment of material science, structural engineering, and market demands, empowering you to lead confident, productive conversations with any sex toy manufacturer and turn your vision into a profitable reality.

The Definitive Answer for Brands, Retailers, and Wholesalers

For any business serious about creating a successful private label sex toy, mastering product development comes down to three non-negotiable pillars. Success isn’t about finding the cheapest option; it’s about making the smartest choices for your target market and brand identity.

-

📌 Material Mastery: It Starts with Silicone Hardness

The "feel" of your product is everything, and this is dictated by Shore hardness. This scale (typically ranging from -20 to 45 Shore A for this industry) governs softness, flexibility, structural integrity, and even how easily the product can be molded. Choosing the wrong hardness is the single most common—and costly—mistake in sex toy design. -

📌 Strategic Structural Design: Balancing Cost and Sensation

The internal architecture of your product is just as important as the material touching the skin. Whether you opt for a cost-effective ABS plastic core with a silicone sleeve or a premium full liquid silicone (LSR) body, this choice directly impacts your unit cost, tactile experience, and production complexity. A top-tier sex toy manufacturer will guide you through these trade-offs. -

📌 Market and Compliance Alignment: Know Your Customer and Their Standards

A product that’s a bestseller in one region may fail in another. Data clearly shows that North American and European markets overwhelmingly prioritize body-safe, FDA-certified materials. Attempting to cut corners with non-certified materials to save a few dollars is a losing strategy that will lock you out of the most lucrative markets.

Why Keep Reading?

Below, we’re pulling back the curtain. You’re about to discover the factory-floor secrets, cost/quality trade-offs, and data-driven strategies that separate market-leading brands from the ones that quietly disappear.

Here, we tackle the most pressing questions brands have when navigating the OEM/ODM sex toys landscape.

1. How Does Silicone Hardness Really Impact Product Performance? 📏

This isn’t just a technical number; it’s the heart of the user experience.

The Shore hardness scale is your guide to texture and function. Here’s a simple breakdown from a manufacturing perspective:

| Hardness Range | Best For & Manufacturing Insight |

|---|---|

| -20° to 0° | Ultra-Soft Products (Realistic Dildos, Sleeves): This range delivers an incredibly lifelike, "skin-like" feel. 💡 Insider Tip: Achieving this requires liquid silicone rubber (LSR) and highly skilled manufacturing. Be wary of any supplier offering this with solid silicone, as defect rates can be astronomical. |

| 15°–35° | Medium-Firm All-Rounders (Vibrators, Massagers): This is the sweet spot for most products. It offers a great balance of satisfying firmness, flexibility, and durability. It’s also more forgiving in the molding process, making it a reliable choice for your first customized sex toy. |

| 40°–45° | Rigid & Structural Components (Plug Bases, Internal Supports): This hardness provides the essential rigidity needed for bases of anal toys or internal chassis that hold electronics. It’s about safety and structure, not softness. |

Critical Trade-Off: User Comfort vs. Durability

- Lower Shore (0°-15°): Delivers an unparalleled premium feel but is more delicate and prone to higher defect rates during molding if not handled by an expert sex toy manufacturer. The raw material cost is also higher.

- Higher Shore (25°+): Exceptionally durable and cost-effective to produce, but can feel less realistic or "hard" if used for the main body of a product intended to be soft.

2. What Structural Designs Actually Balance Cost and Quality? 🏗️

Let’s talk architecture. When you design a sex toy, you’re an architect of pleasure, and your material choices are your building blocks. Here are the top 3 designs used in products made in China and worldwide:

| Design | ✅ Pros | ❌ Cons | 💰 Ideal For & Price Point |

|---|---|---|---|

| 1. ABS + Solid Silicone Sleeve | Low tooling cost, fast production, easy to repair/disassemble. | Can feel less “premium” as the seam between plastic and silicone is often detectable. Less realistic feel. | Budget-friendly vibrators and mass-market products ($15–$30 retail). |

| 2. Full-Liquid Silicone (LSR) | The gold standard. Seamless, velvety feel, fully waterproof, and perceived as highly luxurious and body-safe. | Highest material waste (can be 30%+), more complex tooling, and higher unit cost. | Premium and luxury brands aiming for the top shelf ($50–$150+ retail). |

| 3. Hybrid (ABS Core + LSR Overmold) | The perfect compromise. Offers a seamless, high-quality LSR exterior with the cost-effectiveness and structural integrity of an internal ABS chassis. | Complex assembly can increase labor costs. Requires advanced OEM/ODM sex toys capabilities. | Dominant in the mid-range market, offering premium features without the luxury price tag ($30–$70 retail). |

3. How Do You Align Your Design with What the Market Demands? 🌍

Creating a great product is only half the battle; you need to create the right product for your target audience.

Regional Preferences & Compliance (2023 Data Insights):

- North America & Europe: An overwhelming 78% of consumers list "body-safe, phthalate-free materials" as a top-three purchasing factor. For these markets, FDA and CE (ROHS) certifications are not optional—they are your ticket to entry. Leading brands actively market these certifications.

- Asia-Pacific: While safety is growing in importance, consumer data shows 63% of purchases are heavily influenced by compact, discreet designs and a more accessible price point ($20–$50).

Brand Positioning in Action:

- For a Premium Brand: Your path is clear. Use full-LSR construction or a sophisticated dual-layer LSR (e.g., a firm inner core with an ultra-soft outer layer). You will market the specific Shore hardness as a feature (e.g., "Featuring 10° Skin-Real™ Silicone") and prominently display your medical-grade material certifications.

- For a Mass-Market Brand: Your focus is on value and reliability. The ABS hybrid model is your workhorse. Your marketing should highlight features like 100% waterproofing, powerful vibration patterns, and a solid warranty, assuring customers of quality at an affordable price.

4. Liquid Silicone (LSR) vs. Solid Silicone: What’s the Real Difference?

This is a critical conversation to have with your sex toy supplier.

- LSR (Liquid Silicone Rubber): This is a two-part platinum-cured silicone that is injected into a heated mold as a liquid. It allows for incredibly complex shapes, thin walls, and a seamless, perfect finish. It’s the standard for medical-grade and premium private label sex toy products.

- Solid Silicone (HCR): This material starts as a clay-like solid that is compression-molded. It’s more cost-effective but is limited in the softness it can achieve (realistically, ≥25° Shore) and the complexity of the designs. It’s great for simpler shapes and more budget-conscious projects.

🚩 Factory Red Flag: If a potential partner pushes hard for you to use solid silicone for a design that requires ultra-low hardness (≤20°), they are likely trying to cut costs at the expense of your product’s quality. Ask them directly about their expected defect rates for that process. An honest sex toy manufacturer will be transparent.

5. Are There Specific Thickness Guidelines to Follow? 📐

Yes, and they are critical for preventing product failure.

- Vibrator Sleeves: For an overmolded design, a silicone sleeve thickness of 1.5mm to 2mm is ideal. This is thick enough for a plush feel and durability but thin enough to effectively transmit vibrations from the internal motor. A hardness of 25°–35° is typical.

- Dual-Layer Dildos: This advanced technique creates stunning realism. A common and effective combination is a 20° Shore inner core for structural support and a 0° Shore outer layer for that soft, skin-like touch.

6. How Can I Verify a Manufacturer’s Claims? ✅

Trust, but verify. Before committing to mass production, follow this checklist:

- Request Material Certifications: Don’t just take their word for it. Ask for the FDA, ROHS, and REACH certification documents for the specific silicone batch they plan to use for your product.

- Order Samples in Different Hardnesses: Always request physical prototypes in your target Shore hardness, plus samples that are slightly softer and firmer (e.g., if you’re targeting 20°, ask for 15°, 20°, and 25°). Feel is subjective, and holding it in your hand is the only true test.

- Audit Their Defect Rates: Ask them directly, "For a product with this material and structure, what is your average defect rate?" A professional sex toy manufacturer tracks this data and should be able to give you a straight answer. Rates over 5-10% for complex designs should be investigated further.

7. What "Extra" Certifications Make a Difference in 2024? 🏆

While FDA and CE are the baseline for Western markets, savvy brands are going a step further to build ultimate consumer trust. Discuss these with your supplier:

- REACH: A European Union regulation, it concerns the Registration, Evaluation, Authorisation, and Restriction of Chemicals. Compliance shows you are committed to protecting human health and the environment from harmful chemicals, which is a powerful marketing message in the EU.

- Prop 65 (California): If you plan to sell in California, compliance with Proposition 65 is legally required. It mandates warnings about exposure to chemicals known to cause cancer, birth defects, or other reproductive harm. Being Prop 65 compliant from the start saves major headaches and demonstrates a high level of diligence.

A manufacturer who is already familiar with and compliant with these regulations is a strong indicator that you are dealing with an experienced, export-focused partner.

The Final Word

Mastering the interplay of silicone hardness and structural design is not just a technical exercise—it’s the strategic foundation of your brand’s reputation and long-term profitability. Get these elements right, and you will not only create exceptional products that command customer loyalty but also build a powerful and enduring brand in a competitive market.

Latest Articles

February 18, 2026

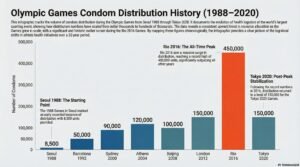

Why Do The Olympics Distribute Hundreds of Thousands of Condoms?

Is the Olympic Village just a global sporting event, or is it the world’s most exclusive party? Imagine 450,000 condoms.

February 17, 2026

Condom Breakage Nightmares: Why Do They Pop and How Can Premium Stock Save Your Brand Reputation?

Imagine this: Your customer is in the heat of the moment based on trust in the product you sold them.

February 16, 2026

Why is she "so dry"? The $600 Billion Missed Opportunity in Female Intimate Wellness?

Problem: It is the number one complaint in the bedroom, yet the most ignored category on your retail shelves. "Why

February 13, 2026

Is Having Sex During Your Period Actually Dangerous?

It’s that time of the month again. You’re feeling a mix of emotions, and maybe, just maybe, your libido is